Visual: Located at the bottom of the engine block, it's a large, heavy shaft with offset journals (crank pins). You may see its pulley or flywheel externally. When exposed, it has rounded journals for the connecting rods to attach.

Aural: When rotating, a healthy crankshaft produces a smooth, consistent whirring sound. Irregular noises like knocking or clanking indicate potential problems.

Visual: Located in the cylinder head (overhead cam engines) or within the engine block (pushrod engines). It has lobes (cams) that actuate the valves. In overhead cam engines, it is visible when the valve cover is removed.

Aural: A properly functioning camshaft produces a smooth, rhythmic ticking sound. Excessive ticking or tapping can indicate wear or damage.

Visual: Pistons are cylindrical components inside the cylinders. Connecting rods connect the pistons to the crankshaft. They are not visible without disassembling the engine. However, signs of problems can be external, such as excessive blow-by (exhaust gases escaping around the pistons).

Aural: Piston slap (a knocking sound) can indicate worn pistons or cylinders. Rod knock (a deep, heavy knocking sound) suggests connecting rod bearing issues.

Visual: These pins connect the pistons to the connecting rods. They are internal and not visible without disassembly.

Aural: A loose gudgeon pin can produce a sharp, metallic clicking or knocking sound.

Visual: Located in the cylinder head, they control the intake and exhaust of gases. You can see the valve stems and valve springs when the valve cover is removed.

Aural: A light, rhythmic ticking sound is normal. Excessive ticking or tapping can indicate valve lash problems or worn components. Whistling sounds can be caused by leaking valves.

Visual: The top part of the engine, it houses the valves, camshaft (in overhead cam engines), and spark plugs or injectors. It is a large metal component bolted to the top of the engine block.

Aural: Head gasket leaks can produce hissing or bubbling sounds, especially when the engine is running.

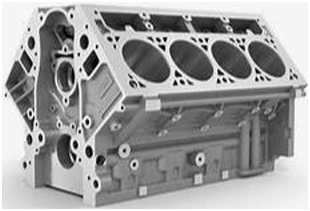

Visual: The main body of the engine, it contains the cylinders, crankshaft, and coolant passages. It is a large, heavy metal casting.

Aural: Cracks or leaks in the engine block can produce hissing or gurgling sounds, especially when the engine is hot.

Visual: Located around the valve stems, they close the valves after they are opened by the camshaft. They are coiled springs.

Aural: Broken or weak valve springs can produce a rattling or clattering sound, and misfires.

Visual: These are located at points where rotating components meet stationary ones (e.g., crankshaft bearings, camshaft bearings). They reduce friction. They appear as smooth metal surfaces or rollers.

Aural: Worn bearings can produce a rumbling, grinding, or whining sound.

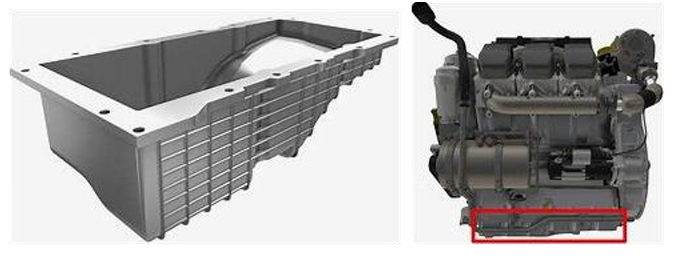

Visual: The lowest part of the engine, it holds the engine oil. It's a metal or plastic pan bolted to the bottom of the engine block.

Aural: Damage to the sump can lead to oil leaks, which may not produce a sound but will result in visible oil dripping.

Visual: Tappet covers (valve covers) seal the top of the cylinder head, preventing oil leaks. The front cover protects the timing gears or chains. They are typically metal or plastic covers.

Aural: Leaks from these covers can result in hissing or dripping sounds.

Visual: These are toothed wheels that transmit motion between shafts (e.g., timing gears, oil pump gears). They are visible when covers are removed.

Aural: Worn or damaged gears can produce a whining or grinding sound.

Visual: These are flexible bands that transmit power between pulleys (e.g., serpentine belt, timing belt). They are usually made of rubber.

Aural: Worn or loose belts can produce a squealing or chirping sound.

Visual: These are metal links that transmit power between sprockets (e.g., timing chain). They are stronger than belts.

Aural: Worn or loose chains can produce a rattling or slapping sound.

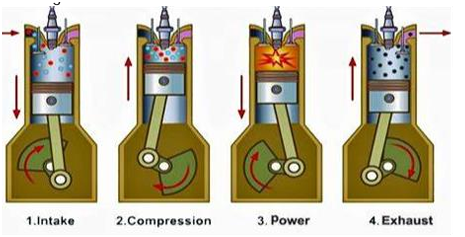

This cycle completes one power stroke in four piston strokes (two crankshaft revolutions).

The four strokes are:

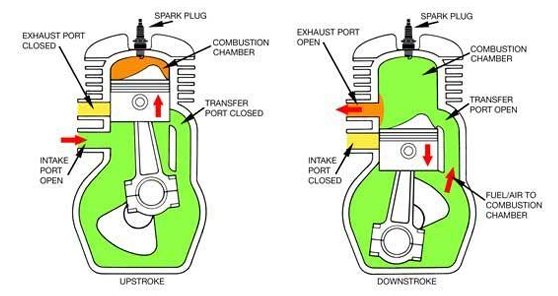

This cycle completes one power stroke in two piston strokes (one crankshaft revolution).

These engines use compression to ignite the fuel.

The lubrication system is critical for the smooth operation and longevity of an engine. Its primary functions are:

Regular oil and filter changes are essential for maintaining the lubrication system's effectiveness.

An engine tune-up aims to restore optimal engine performance by addressing various factors, including the valve train, engine timing, and ignition timing.

Purpose: Valves control the intake of air-fuel mixture and the exhaust of combustion gases. Proper valve operation is essential for efficient engine performance.

Properly adjusted valves ensure proper cylinder sealing, optimal combustion, and efficient engine operation.

Purpose: Engine timing refers to the coordination of the crankshaft and camshaft(s). It ensures that valves open and close at the correct times relative to piston movement.

Correct engine timing is crucial for optimal engine performance, fuel efficiency, and emissions control.

Purpose: Ignition timing refers to the timing of the spark plug firing in relation to piston position. It ensures that the air-fuel mixture ignites at the optimal moment for efficient combustion.

Correct ignition timing ensures complete combustion, optimal power output, and reduced emissions.